Test Stand with IntelliMESUR® F755 / F1505

Important Note: The motorised test stand models ESM750, ESM750S, ESM1500 and ESM1500S have been discontinued and replaced by the F755 and F1505 models of the Series-F with IntelliMESUR.

The Series F IntelliMESUR® test stands integrate the functionality of a bench dynamometer with a modular, robust design, offering precise tension and compression testing with load capacities from 3.4 kN up to 6.7 kN. These systems are ideal for both industrial and research environments, combining cutting-edge technology with an intuitive interface that allows you to measure force and displacement, configure tests, and analyse results quickly and easily. Thanks to their compatibility with FS05 and R07 force sensors – with the AC1083 adapter required for the FS05 series – and IntelliMESUR® software, these test stands adapt to a wide range of applications in industrial and research settings.

Key Features:

- Integrated IntelliMESUR® System: Enables you to configure, execute and analyse tests from a centralised interface, simplifying both basic and sequenced test setups.

- 10-Inch Touch Panel: Offers an intuitive and visual user experience, speeding up test setup and monitoring while reducing the learning curve.

- Advanced Connectivity: Equipped with two independent USB‑C ports for direct PC connection and external data storage, facilitating efficient data management.

- Compatibility and Adaptability: Works with FS05 and R07 force sensors and is complemented by the AC1083 adapter for the FS05 series, ensuring versatile measurement capabilities.

- Flexible Configurations: Available in various models and heights, allowing adaptation to diverse testing requirements and optimising use in limited or specific spaces.

Key Benefits:

- Ease of Use: The integration of IntelliMESUR® software and the touch panel reduces the learning curve, enabling users of any level to configure and execute tests with confidence.

- Accurate and Customised Results: High-precision measurements of force and displacement facilitate the generation of detailed reports and custom graphs, optimising quality control.

- Operational Efficiency: Advanced connectivity and the ability to store and export data streamline analysis and decision-making, reducing operational times.

- Scalability and Adaptability: Its modular design allows you to expand functionalities through customised configurations, adapting to the growth and diversification of your testing needs.

Contact us for more information or to place an order. Our expert team is ready to assist you in selecting and configuring the IntelliMESUR® test stand that best suits your operational and technical needs, ensuring precise and reliable test results for your projects.

Features

- Test Creation Wizard: Simplify test setup with step‑by‑step guides that guarantee optimal results without complications.

- Integrated Motion Control and Data Collection: Enables precise control of displacement and real‑time data capture, enhancing test quality.

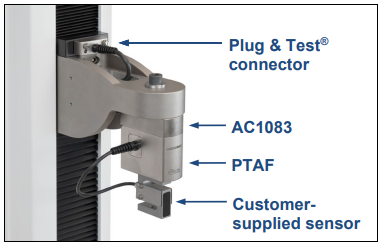

- Versatile Plug & Test® System: Compatible with load cells from other manufacturers via the PTAF adapter, expanding your measurement options.

- FollowMe® Function: Allows dynamic adjustment of the crosshead by pushing and pulling the force sensor, adapting to variations during testing.

- System Deflection Compensation: Automatically corrects any inherent deviations in the system, ensuring precise measurements.

- Auto-Return Function: Resets the probe to its initial position after each test, optimising operational efficiency.

- Overload Protection: Incorporates safety mechanisms to prevent damage under extreme test conditions.

- Secure User Access: Features a three-level permission system, protected by a password, allowing controlled system use by different users.

The F755, F755S, F1505, and F1505S force test stands are shipped as a complete kit, including the following accessories:

- 1 Control panel, mounting bracket, and hardware (-IMT models only)

- 1 USB flash drive containing software installation files (-IM models only)

- 1 USB dongle (-IM models only)

- 1 USB cable

- 1 Eye end kit for base

- 2 Lock rings for eye end

- 2 Spanner wrenches

- 1 Power cord

- 1 Allen wrench set

- 1 NIST-traceable calibration certificate

The F series equipped with IntelliMESUR® offers advanced analysis capabilities and technical requirements for strength testing. It features options for a 10.1-inch display or screenless models for PC connection, ideal for advanced industrial research and development laboratories.

- Advanced Functions: Includes all the features of EasyMESUR® plus overlaying previous journeys and measuring the COF.

- Versatility and Precision: Capability to perform basic and complex tests, with options to extend columns and add screen protectors.

The Series F force testers from Mark-10 are available in 2 versions EasyMESUR® and IntelliMESUR®.

While both systems are designed for testing tensile and compression forces, the sytems serve a different user category. This is reflected in the size of the screen, the possibilities in complexity in setting up and running tests and analyzing the data.

EasyMESUR® is setup as a basic cost effective system that can be modular upgraded with required functionalities. Upgrades come a single functions like distance measurement, load holding, break detection etc., or as packages where functionalities are combined for specific tasks.

The system comes standard in evaluation mode where all functionalities are operational for the first 160 hours of use, aftir this only the purchased functionalities will remain operational. Additional functionalities can be purchased through a code.

EasyMESUR® is operated from a 7”tablet that uses its own software and is not compatible with windows, the system can be operated from a pc using third party software.

IntelliMESUR® comes as a complete advanced platform with only a few available upgrades.

It uses a 10.1” Windows tablet to operate the test stand and it can handle Basic tests like

Limit testing to a load, break, or distance, Height measurement, Load holding, Cycle testing and multi step tests combining the basic tests. With a capture rate of 1000 Hz, a peak load capture rate of 20.000 Hz and a maximum amount of datapoints per run of 1.000.000 all test data is captured and stored.

IntelliMESUR® comes with a test setup wizard and graphing and reporting standard.

The optional materials testing calculations module can Characterize and analyze the behavior of materials, components, and assemblies with a suite of materials testing calculations.

The Coefficient of Friction Testing module measures static and dynamic COF for a wide range of materials according to relevant standards.

EasyMESUR® is the platform to chose when a basic test is required, the stand can be upgraded with specific functionalities to cater flexibility.

IntelliMESUR® is the best platform when advanced tests are required, this platform comes with extended test, analysis and reporting capabilities.

| Feature / Specification | IntelliMESUR® | EasyMESUR® |

|---|---|---|

| Basic test wizards | Included | Included |

| Multi-step tests | Included | - |

| Extended speed ranges | Included | Option |

| Distance measurement, distance limits, and preload | Included | Option |

| Auto-return and cycling | Included | Option |

| Break detection | Included | Option |

| Load holding | Included | Option |

| FollowMe® crosshead positioning | Included | Option |

| Batch testing | Included | - |

| Operator prompting | Included | - |

| Pass / fail limits | Included | Included |

| Report creator | Included | Option |

| Results | Large selection | 1 per test |

| Graphing and statistics | Included | Option |

| Overlay previous runs on graph | Included | - |

| PC control via third-party application | - | Option |

| Coefficient of friction (COF) measurement | Option | - |

| Overload protection | Included | Included |

| Accuracy - force sensor | ±0,1% or ±0.15% of sensor full scale | ±0,1% or ±0,15% of sensor full scale |

| Accuracy - test stand | ±0,1% of sensor full scale | ±0,1% of sensor full scale |

| Distance resolution | 0.01 mm | 0.02 mm |

| System deflection compensation | Included | Included |

| Accuracy - distance | ±0.05 mm, at any load or position | ±0,15 mm, at any load or position |

| Accuracy - speed | 0,2% of setting | 0,2% of setting |

| Peak load capture rate | 20.000 Hz | 5.000 Hz |

| Data acquisition rate | 1.000 Hz | 100 Hz |

| Number of data points per run | 1.000.000 | 100.000 |

| Users and permissions | 3 permission tiers, unlimited users | 1 tier (password access) |

| Runs on | Windows tablet or PC | Control panel only |

|

|

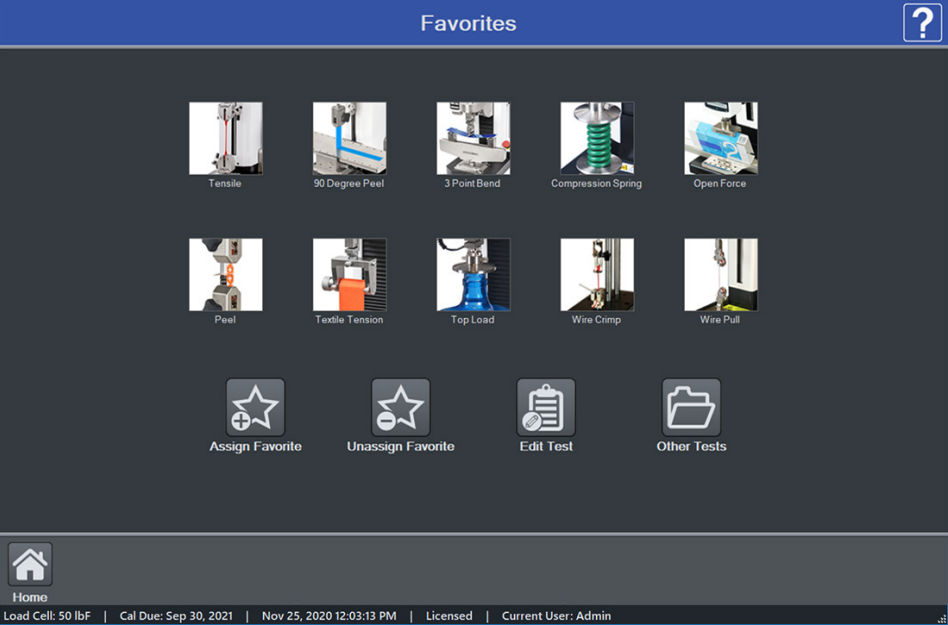

Quick access favorites screenQuickly access up to 10 favorite tests. Associate an image with each favorite for easy identification. Define your own favorites for faster test setup. |

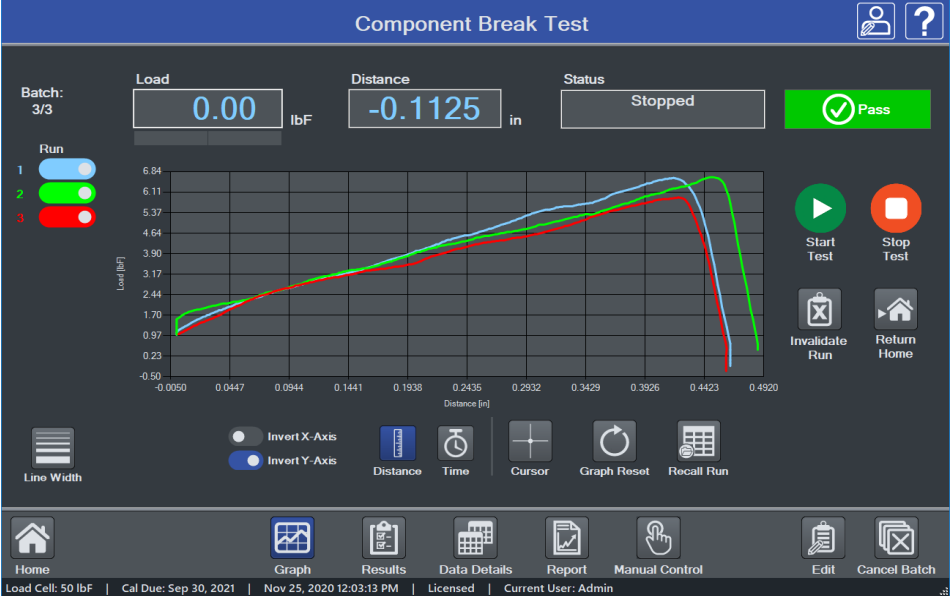

Point of view, Graph screenThe Graph view plots force vs. distance or force vs. time. Overlay up to 10 runs for visual comparisons. |

|

|

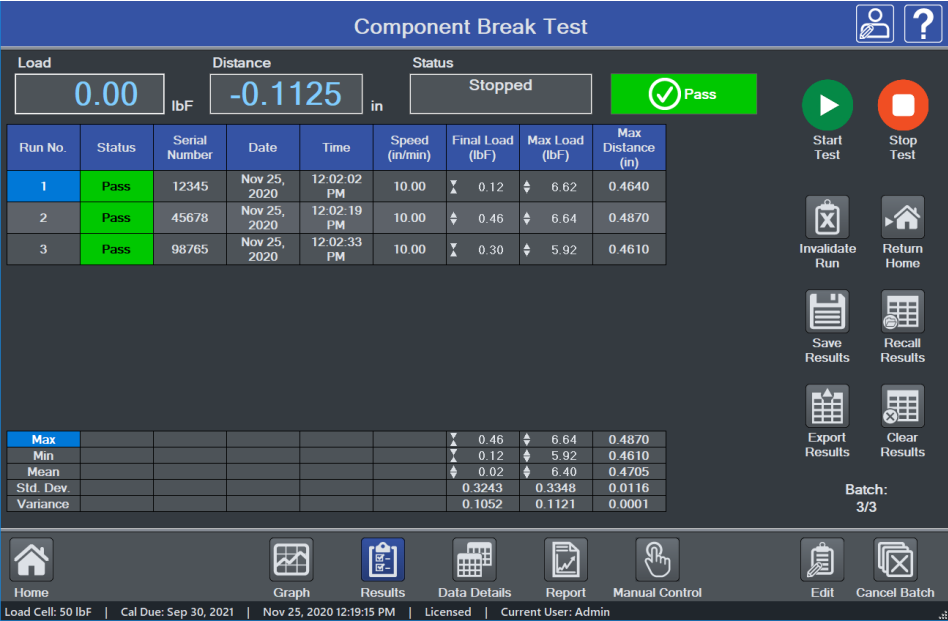

Point of view Results screenThe Results view displays user selected results for each run. Statistics may be applied to selected results. |

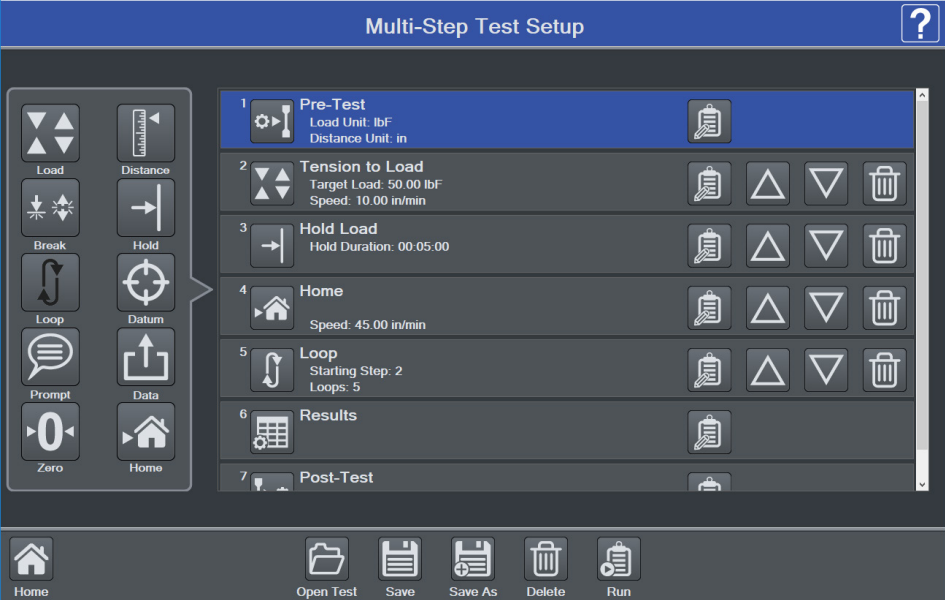

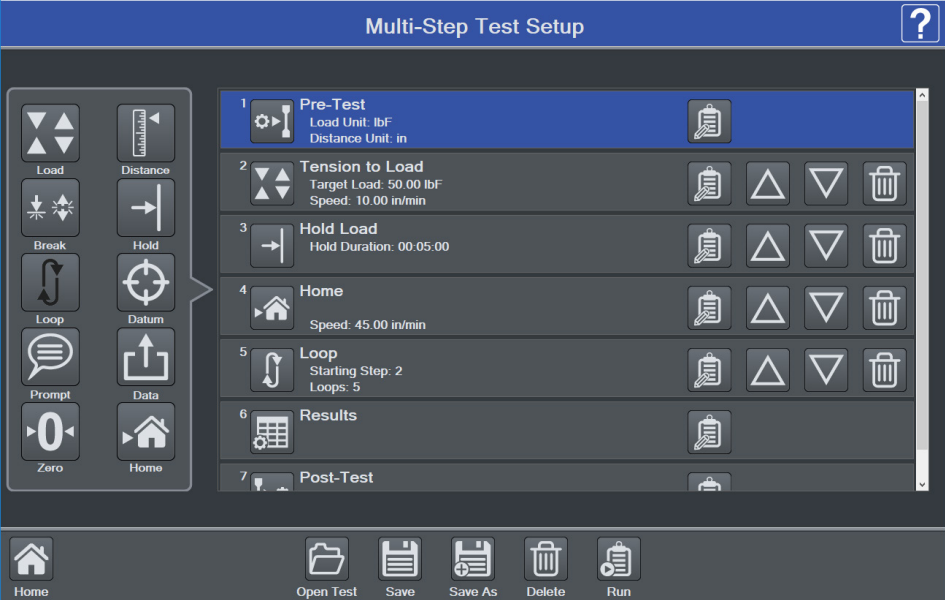

Multi-step test setupBuilding upon basic test wizards, easily incorporate any combination of steps, with the ability to loop a sequence of steps. |

|

|

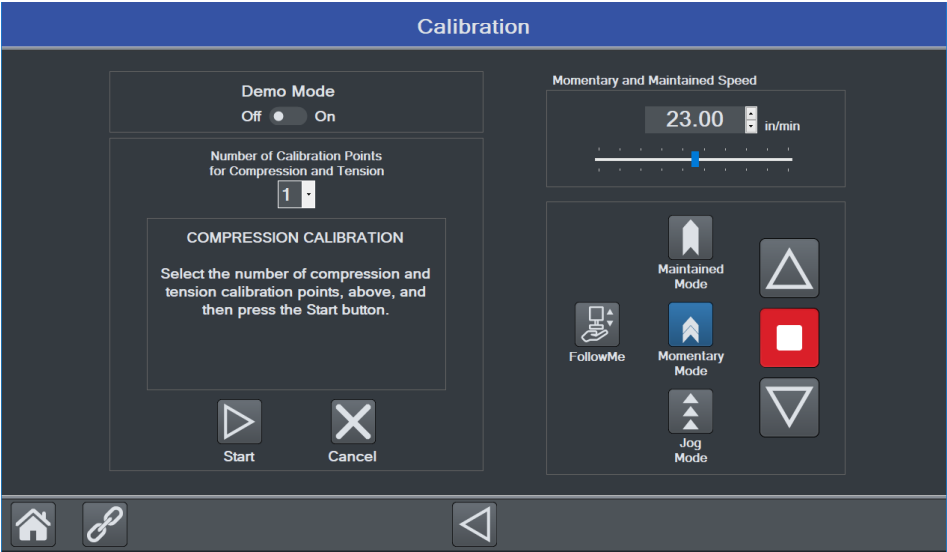

Intelligent manual controlManually control the test stand to obtain quick force and distance results, or manually position the crosshead prior to a test. Select from several actuation methods, including momentary (buttonhold), maintained (button release) motion, jog mode with three distance presets. |

Calibrate force sensorsIntelliMESUR® provides an integrated utility, with an intuitive step-by-step wizard. Manual controls allow the technician to use the test stand to apply tension and compression forces. Alternatively you can remove the force sensors for off-site calibration with a Mark-10 Model M7I or M5I indicator. |

|

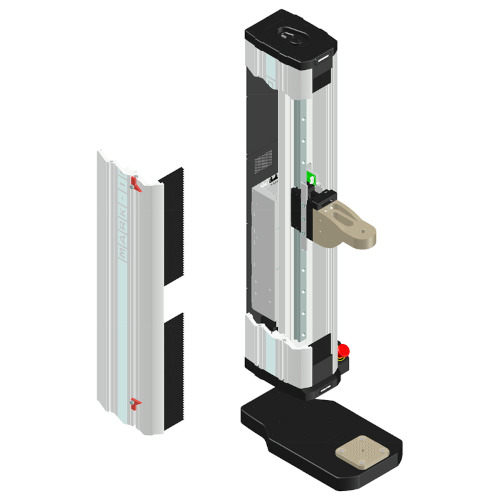

Rigid design |

|

External limit switches Solid-state upper and lower limit switches may function as test limits as well as test exceptions. Dual-graduated rulers aid in switch placement. |

|

Easy-to-service electronics Most electronics are housed in an integrated module. They are easily replaced without special tools or processes. |

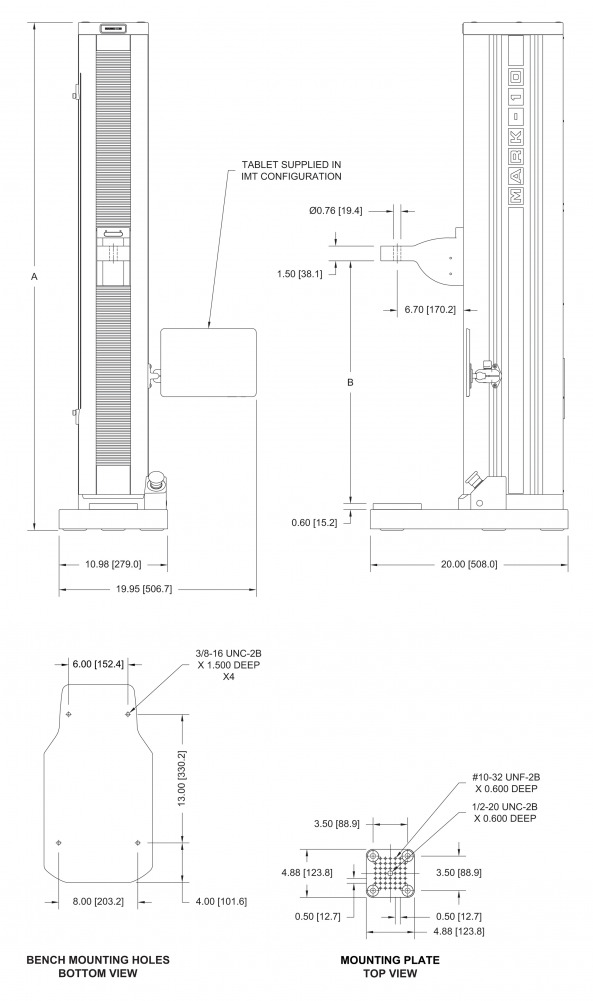

Dimensions

| Model F755 | Model F755S | Model F1505 | Model F1505S | |

|---|---|---|---|---|

| Load capacity | 3,4 kN | 3,4 kN | 6,7 kN | 6,7 kN |

| Maximum travel distance | 813 mm | 360 mm | 813 mm | 360 mm |

| Speed range | 0,02 - 1,525 mm/min | 0,02 - 1,525 mm/min | 0,02 - 1,800 mm/min | 0,02 - 1,800 mm/min |

| Load accuracy (% of full scale) |

|

|

|

|

| Load sampling rate | 20.000 Hz | 20.000 Hz | 20.000 Hz | 20.000 Hz |

| Data acquisition rate | 1.000 Hz | 1.000 Hz | 1.000 Hz | 1.000 Hz |

| Speed setting accuracy | ±0,2% | ±0,2% | ±0,2% | ±0,2% |

| Distance accuracy | ±0,05 mm, factory-compensated at up to full load | ±0,05 mm, factory-compensated at up to full load | ±0,05 mm, factory-compensated at up to full load | ±0,05 mm, factory-compensated at up to full load |

| Distance resolution | 0,01 mm | 0,01 mm | 0,01 mm | 0,01 mm |

| Limit switch repeatability | ±0,03 mm | ±0,03 mm | ±0,03 mm | ±0,03 mm |

| Power | Universal input 100-240 VAC, 50/60 Hz, 120W | Universal input 100-240 VAC, 50/60 Hz, 120W | Universal input 100-240 VAC, 50/60 Hz, 450W | Universal input 100-240 VAC, 50/60 Hz, 450W |

| Fuse type | 4A, 3AG, SLO BLO | 4A, 3AG, SLO BLO | 4A, 3AG, SLO BLO | 4A, 3AG, SLO BLO |

| Weight | 83 kg (test stand) 107 kg (shipping weight) | 68 kg (test stand) 88 kg (shipping weight) | 89 kg (test stand) 112 kg (shipping weight) | 71 kg (test stand) 93 kg (shipping weight) |

| Environmental conditions |

|

|

|

|

| Conformance | CE mark | CE mark | CE mark | CE mark |

| Warranty | 3 years | 3 years | 3 years | 3 years |

Load capacity is reduced at higher speeds, as follows: - F755 / F755S: limited to 2,3 kN above 900 mm/min - F1505 / F1505S: limited to 4,5 kN above 1.525 mm/min |

||||

Plug & Test® Sensors for the Series F

Mark-10’s Series F test stands employ a specialised version of Plug & Test® sensors for compression and tension testing. These sensors store calibration and configuration details within an internal PCB, allowing seamless interchangeability across multiple stands. Currently, the FS05, FS06, and R07 are available for use with the Series F range.

- FS05

- Capacities range from 0.5 kN to 2.5 kN.

- Connects directly to the F105, F305, and F505 test stands.

- Requires the AC1083 adapter for use with the F755 or F1505 stands.

- FS06 and R07

- Designed for both compression and tension applications.

- Make use of the Mark-10 operating system within the Series F test stands.

Through Mark-10’s Plug & Test® technology, all sensors store their own configuration and calibration information on-board, ensuring consistent and accurate readings when moved from one test stand to another.

PTAF Adapter

Designed for third-party strain gauge load cells, force, and torque sensors, the PTAF adapter offers exceptional flexibility for your Series F testing system:

- Direct Connectivity

- Attaches to F105, F305, and F505 stands without additional hardware.

- Compatible with the F755 and F1505 stands, as well as M5I and M7I indicators, using the AC1083 adapter.

- Configurable Capacities

- A user-friendly software utility allows the PTAF to be programmed with a wide library of common capacities, from 0.5 N up to 4,000 kN in force measurement and from 7 Ncm up to 57,000 Nm in torque measurement.

- Identification and Interchangeability

- Each adapter can be assigned an identification number, displayed upon power-up or on the test stand’s screen.

- All calibration and configuration data is stored within the adapter’s PCB, enabling quick swapping between sensors and indicators without loss of accuracy.

Whether you require direct connectivity for Mark-10’s native Plug & Test® sensors or need to integrate existing third-party devices, the PTAF adapter provides a versatile, reliable solution for your force and torque measurement needs.

|

|

|

By removing the circuit board and side cover the third party sensor you can be connected to the PTAF adapter |

Feed the cable through and connect the wires to the terminal block. |

|

|

|

Replace the circuit board and side cover. |

The sensor can now be configured using the included , Plug & Test Adapter Configuration software and used on the Series-7 test stands. An extra adapter (AC1083) is required to connect the PTAF to the F755(S)/F1505(S) range test stands. |

Test stand with IntelliMESUR® F105 / F305 / F505 / F505H

- Integrated Force Sensor: Provides a cable-free interface for the FS05 force sensor.

- Integrated Touchscreen Control Panel: For setting up, running, and analysing data via the IntelliMESUR® control panel.

- Integrated Motion Control and Data Collection: The Plug & Test® system allows seamless use of third-party load cells via the PTAF adapter.

More details

Test Stand with EasyMESUR® F105 / F305 / F505 / F505H

- Integrated Force Sensor: Seamless interface for the FS05 force sensor without cables.

- Integrated Touchscreen Control Panel: For setting up, running, and analysing data via the Easy MESUR® software.

- Test Creation Wizards: Guides that assist the user throughout the configuration process.

More details

Test stand with EasyMESUR® F755 / F755S / F1505 / F1505S

- Cable-Free FS05 Force Sensor Interface: Integrates a force sensor with an optimised cable-free interface for the FS05, ensuring interference-free measurements.

- Integrated Touchscreen Control Panel: Provides an intuitive user experience for centralised test setup, execution, and monitoring.

- Comprehensive Management via EasyMESUR®: Enables configuration, execution, and analysis of data directly through the integrated system, optimising workflow.

More details

Model-3I Force/Torque Indicator

- Interchangeable force and torque sensors through Plug & Test® technology (sensors are sold separately)

- High-speed 2.000 Hz sampling rate

- Ultra-compact size

More details

Model-5I Advanced Digital Force/Torque Indicator

- Interchangeable force and torque sensors through, separately sold, Plug & Test® technology

- High-speed 7.000 Hz sampling rate

- USB, RS-232, Mitutoyo, and analog outputs

More details

Model-7i Advanced Force/Torque Indicator

- Interchangeable force and torque sensors through Plug & Test® technology (sensors are sold separately)

- High-speed 14.000 Hz sampling rate

- Continous data capture of up to 5.000 data points, at up to 14.000 Hz, downloadable to a PC

- 5 units of measurement, plus Coefficient of Friction and user-defined unit with configurable name

More details

Accessories

IMF002 Materials Testing Calculations Module for IntelliMESUR®

- Direct Integration: Exclusively compatible with IntelliMESUR® systems for hassle-free setup.

- Customisable Results: Ability to define custom criteria such as offset yield, rupture threshold, or measurement units.

- Comparative Curves: Display multiple tests in parallel for advanced graphical analysis.

- Limitation: Calculations are not available for multi-step tests.

More details

Series R07 Force Sensors for Series F Test Stands

- Compatible with Models F755, F1505, and F1505S test stands

- Measure tension and compression force

- Member of the Plug & Test® family of interchangeable sensors and indicators (adapter required)

More details

PTA PTA/PTAF Plug & Test Load Cell Adapter

- Compatible with strain gage-based load cells, force sensors, and torque sensors

- Program the adapter via USB or RS-232 through the indicator

More details

Series FS05 Series FS05 Force Sensors

- Mount directly to crosshead of models F105, F305, F505, and F505H without any connection cables

- Member of the Plug & Test® family of interchangeable sensors and indicators (adapter required)

- Measure tension and compression force

More details

Category Force Gauge Accessories

Large assortment of grips, attachments and other accessories for analog and digital force gauges.

More details

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request