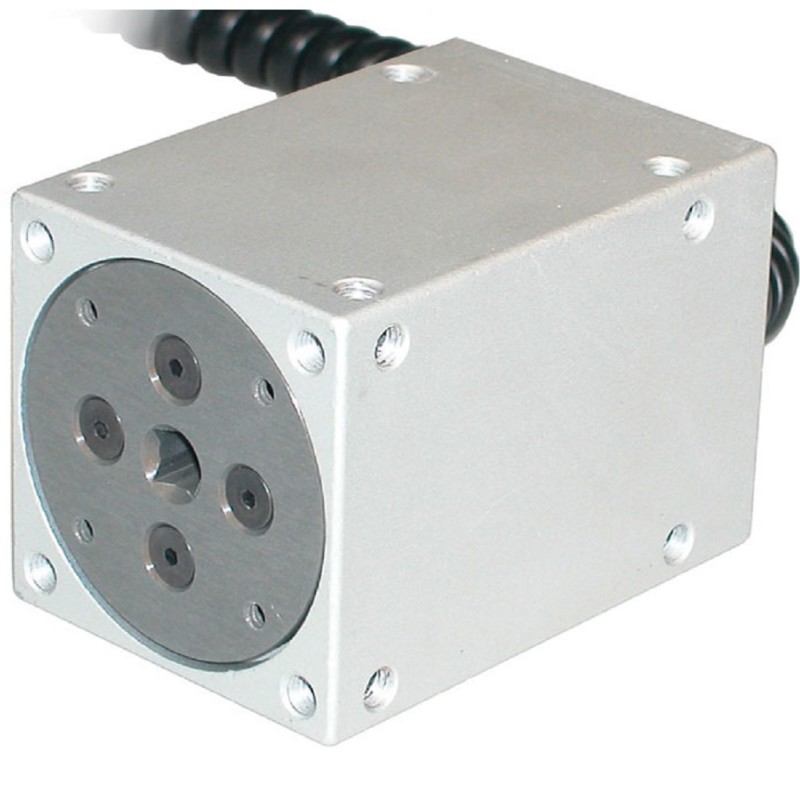

R52 Series Torque Sensor for calibrating tools

The Series R52 torque sensors are developed as a bi-directional torque tool calibration sensor, as basic tester combined with an optional Indicator or as part of a larger torque testing system. With its square design and tapped holes on every surface it can be mounted in virtually direction and setup. A tabletop mounting kit, AC1006, and two different size chucks, AC1014 and AC 1014-1, are sold separately. The Series R52 sensors are available in 6 versions ranging from 7 Ncm to 11,5 Nm.

The sensor connects to an I3, I5 or I7 indicator (sold separately) using the Plug & Test® system. This stores the calibration and configuration data in its internal PCB.

Delivery includes a certificate of calibration which contains 10 data points in each measuring direction.

We are happy to assist you in finding the most suitable configuration for your needs. Please contact us for more information.

Features

- Rugged aluminum housing

- Universal mounting

- May be used for torque tool calibration or as a component of a torque testing system

- NIST-traceable certificate of calibration included

- Unique Plug & TestTM connector holds all calibration and configuration data

- Capacities available from 7 to 1150 Ncm

- 3 years warranty

General information

Mark-10 M7I, M5I, and M3I indicators are used in combination with Plug & Test® sensors and can therefore accommodate numerous force and torque measurement requirements, from 1 N to 50 kN (0.25 to 10,000 lbF) of force, and from 7 Ncm to 550 Nm (10 ozFin to 5,000 lbFin) of torque.

Plug & Test® sensors can be used handheld or mounted to a fixture or test stand for more accurate and repeatable testing results.

The sensors are separately calibrated therefore they can be disconnected from one indicator and connected to another without the need for re-calibration or re-configuration as this is stored in the PCB located inside the smart connector.

Accuracy

System accuracy is determined by the combination of Indicator and sensor combined. To determine the total system accuracy the accuracy value of the sensor is added to the value of the indicator.

As the Indicators have different accuracy values the total system accuracy may vary between the different indicator/sensor combinations. Indicator Model Accuracy M7I / M5I ±0,1% of full scale M3I ±0,2% of full scale.

Example 1 Model MR01-100 sensor with Model M5I Indicator MR01-100 ±0,15% of full scale + M5I ±0,1% of full scale = Total ±0,25% of full scale This translates into a fixed error of up to: 0,25% x 500 N = 1,25 N

Example 2 Model MR50-50Z sensor with Model M3I Indicator MR50-50Z ±0,35% of full scale + M3I ±0,2% of full scale = Total ±0,55% of full scale This translates into a fixed error of up to: 0,55% x 50 Ncm = 0,275 Ncm

Because accuracy is defined as a percentage of full scale, the fixed error is possible anywhere on the scale from 0 to the capacity. As such, this value represents an increasingly large error as percentage of reading towards the low end of the scale. It is, therefore, recommended that a sensor is selected with capacity as close as possible to the expected load. The resolution may be different for some sensors depending on whether a M7I, M5I, or M3I indicator is being used. For example, a Series R01 force sensor will display finer resolution when connected to a M5I indicator than when connected to a M3I indicator.

| Model | Nm | Ncm | Nmm | kgFmm | gFcm | lbFft | ozFin | lbFin |

|---|---|---|---|---|---|---|---|---|

| MR52-10Z | - | 7 x 0,005 | 70 x 0,05 | 7 x 0,005 | 700 x 0.5 | - | 10 x 0,005 | - |

| MR52-20Z | - | 14 x 0,01 | 140 x 0,1 | 14 x 0,01 | 1400 x 1 | - | 20 x 0,01 | - |

| MR52-50Z | - | 35 x 0,02 | 350 x 0,2 | 36 x 0,02 | 3600 x 2 | - | 50 x 0,02 | - |

| MR52-12 | 1,35 x 0,001 | 135 x 0,1 | - | - | - | 1 x 0,0005 | 192 x 0,1 | 12 x 0,005 |

| MR52-50 | 5,7 x 0,005 | 570 x 0,5 | - | - | - | 4 x 0,002 | 800 x 0,5 | 50 x 0,02 |

| MR52-100 | 11,5 x 0,005 | 1150 x 0,5 | - | - | - | 8 x 0,005 | 1600 x 1 | 100 x 0,05 |

| Model | Ncm | kgFmm | ozFin | lbFin |

|---|---|---|---|---|

| MR52-10Z | 7 x 0,005 | 7 x 0,005 | 10 x 0,01 | - |

| MR52-20Z | 14 x 0,01 | 14 x 0,01 | 20 x 0,02 | - |

| MR52-50Z | 36 x 0,05 | 36 x 0,05 | 50 x 0.05 | - |

| MR52-10 | 135 x 0,1 | - | 192 x 0,2 | 12 x 0,01 |

| MR52-50 | 570 x 0,5 | - | 800 x 1 | 50 x 0,05 |

| MR52-100 | 1150 x 1 | - | 1600 x 2 | 100 x 0,1 |

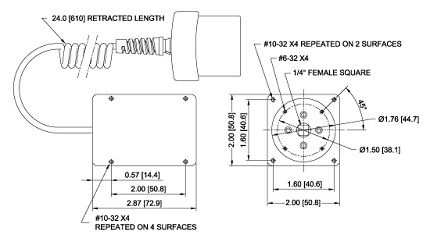

Dimensions

Accessories

Specifications

| Accuracy: | ± 0,35% of full scale + indicator |

| Weight: | 0,5 kg |

| Shipping weight | 1,4 kg |

| Warranty: | 3 years |

Model-3I Force/Torque Indicator

- Interchangeable force and torque sensors through Plug & Test® technology (sensors are sold separately)

- High-speed 2.000 Hz sampling rate

- Ultra-compact size

More details

Model-5I Advanced Digital Force/Torque Indicator

- Interchangeable force and torque sensors through, separately sold, Plug & Test® technology

- High-speed 7.000 Hz sampling rate

- USB, RS-232, Mitutoyo, and analog outputs

More details

Model-7i Advanced Force/Torque Indicator

- Interchangeable force and torque sensors through Plug & Test® technology (sensors are sold separately)

- High-speed 14.000 Hz sampling rate

- Continous data capture of up to 5.000 data points, at up to 14.000 Hz, downloadable to a PC

- 5 units of measurement, plus Coefficient of Friction and user-defined unit with configurable name

More details

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request