DX2-EDM Wire EDM Tension Meter

Manufacturers of wire-EDM machines recommend checking the erosion wire tension once a week. Depending on the machine type as well as the wire material and diameter, the measured tension should lie between 50 and 3000 g.

Manufacturers of wire-EDM machines recommend checking the erosion wire tension once a week. Depending on the machine type as well as the wire material and diameter, the measured tension should lie between 50 and 3000 g.

The correct erosion wire tension reduces wire oscillation and guarantees a pinpoint accuracy of your machines. Always check the tension in calibration mode on the moving wire. Make sure the generator is switched off for the tension check.

Features

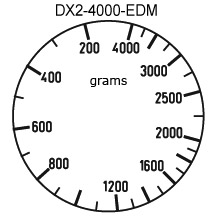

- Easy to operate and read analog scale

- Special finger support located on the rear side reduces the effort to move the outer roller assembly

- Ball-bearing mounted, V-grooved guide rollers

- Roller shifting mechanism ensure easy acquisition of the running material

- Everything in operator's view:

- the guide rollers

- the measured material

- the readings - Each instrument is individually calibrated for highest accuracy

- Certificate of Compliance with the order 2.1 according DIN EN 10204 is included

- Rugged aluminum housing

- Optionally available: Inspection Certificate 3.1 according DIN EN 10204 with calibration report

Dimensions

| Model | Ranges cN | Measuring Head | SCHMIDT Calibration | Material Thickness Compensator | |

| DX2-2000-EDM | 50-2000 | 91 | PA: 0.30 mm Ø | no | |

| DX2-3000-EDM | 100-3000 | 91 | PA: 0.30 mm Ø | no | |

| DX2-4000-EDM | 200-4000 | 116 | PA: 0.30 mm Ø | yes | |

| Other tension ranges and measuring head widths available on request. Other units of measure available, such as g. * Depending on model, either width of wire guide or outer distance between outside guide rollers ** Suitable for 95% of applications - PA = Polyamide Monofilament Special calibration using customer supplied samples is recommended, if process material differs significantly from the SCHMIDT calibration material in diameter, rigidity or shape. For this purpose a material sample of about 5 m should be supplied. | |||||

Specifications

| Calibration: | According to SCHMIDT factory procedure |

| Accuracy: | ±1% full scale or ±1 graduation on scale |

| Scale diameter: | 41 mm |

| Temperature range: | 8 - 45ºC |

| Air humidity: | 85% RH, max. |

| Housing material: | Die-cast aluminum |

| Housing dimensions: | 188 x 85 x 45 mm (LxWxH) |

| Weight, net (gross): | approx. 470 g (1000 g) |

| Rollers: | Material : Hard coated aluminum Diameter: 12 mm |