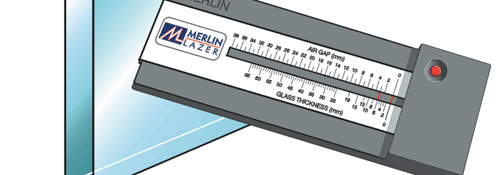

MERLIN LAZER Glass Measurement Gauge

The Merlin Lazer Gauge is a new tool that will revolutionise the way you work and improve your productivity making it the perfect tool for any surveyor who needs to quickly and accurately identity and measure glass in situ.

A remarkably simple but effective precision measurement instrument it allows accurate measurement of glass and air-gap thickness in single, double and triple glazed units.

Simply place the tool onto the corner of the unit and a precise measurement for each piece of glass and the air-cavity will be shown on the calibrated scale.

No access is required to the property and all readings can be taken from one side without the need to remove even a single piece of glass.

It will also measure and identify laminated glass in situ making it the ideal tool for anyone involved in the risk assessment of glass in buildings.

The implications for improved working accuracy, business productivity and profitability are obvious. The Merlin Lazer Gauge allows instant appraisal of all site work, shop fronts, office blocks or indeed any situation where glazing is involved – without the need to remove even a single piece of glass.

Complete with batteries and a high quality protective case the Merlin Lazer Gauge is exceptional value and could easily pay for itself on its first contract.

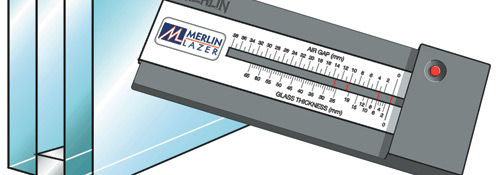

Single glazed - 2 red laser lines visible

Double glazed - 4 red laser lines visible

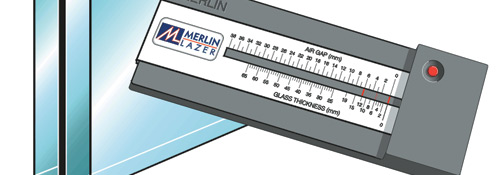

If the unit is double glazed and coated (e.g. K-Glass or Low-E glass), 4 laser lines are visible. One laser line is more intense, this is the one indicating the coated surface.

Double glazed with interface - 3 red laser lines visible

2 clear laser lines indicate the entire depth of glasscoatings. One laser line is thinner than the other, this one indicates the interface. If the interface is extremely thick, two laser lines appear, indicating the interface depth.

Multiple Coatings with lamination Safety or Pyroglass

2 clear laser lines indicate the entire depth of all glasscoatings, thinner laser lines indicate individual glascoatings and interfaces.

Related Products

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request