KXE Warp Tension Meter

The KXE Warp Tension Meter is designed to measure tensions during warping and weaving. The unique sensor configuration provided two 25 mm wide cylindrical rollers for the capture of two groups of yarns, one on each side of the sensor for measurement. Therefore the sensor will be measuring 50 mm of ends while the process is running. The electronic indicator provides for measurement and storage of the critical high and low peaks that will be measured in the weaving operation. These peaks can then be analyzed and used for process evaluation. Stored data can be transferred to a PC and analyzed using the FREE Tension Inspect software.

The KXE Warp Tension Meter is designed to measure tensions during warping and weaving. The unique sensor configuration provided two 25 mm wide cylindrical rollers for the capture of two groups of yarns, one on each side of the sensor for measurement. Therefore the sensor will be measuring 50 mm of ends while the process is running. The electronic indicator provides for measurement and storage of the critical high and low peaks that will be measured in the weaving operation. These peaks can then be analyzed and used for process evaluation. Stored data can be transferred to a PC and analyzed using the FREE Tension Inspect software.

Features

- Portable measuring head to measure yarn groups of weaving and warping machines

- The sensor can easily be engaged or disengaged also while the machine is running

- Storage of last, average, Max, MIN, PEAK-MAX, PEAK-MIN tension values during an operator set measuring period

- 4 different memory modes can be selected by the operator:

Mode S: only statistical values per series are displayed

Mode L: statistics plus 10 displayed values of each series of measurement

Mode C: statistics plus 4000 displayed values arbitrary up to 255 series

Mode F: as C plus higher sampling rate of 100 Hz = values/s - LCD display with illuminated background for better reading

- Adjustable electronic damping for better reading when tension is constantly changing

- Constant measuring width at the yarn group of 50 mm by catch thread system

- Display of the tension meter can be reversed for right and left hand use to reach all measuring positions easily

- 2 interfaces:

Serial Interface: (RS 232) for connecting to a PC

Analog Interface: (0 - 2 V) for connecting to a line recorder - Memory of max. 4000 displayed tension values split up to 255 series of measurements and statistics (Last, AVG, MIN and MAX of displayed values, MIN-PEAK and MAX-PEAK are values measured within a measuring frequency of 5 kHz)

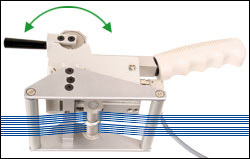

Swivel the lever in direction to the handle to move the reference frame with the support rollers upwards. Hold the measuring head over the yarn group, so that it runs parallel to the measuring feeler and the support rollers. Shove the measuring roller through the yarn group, turn the measuring head by 90° and swivel the lever forward.

Swivel the lever in direction to the handle to move the reference frame with the support rollers upwards. Hold the measuring head over the yarn group, so that it runs parallel to the measuring feeler and the support rollers. Shove the measuring roller through the yarn group, turn the measuring head by 90° and swivel the lever forward.Specifications

| Accuracy | for 10 % to 90 % of range: ±1 % full scale and ±1 digit for remainder of range: ±3 % full scale and ±1 digit |

| Measuring Units | daN |

| Overrange | 10 % full scale, without accuracy guarantee |

| Overload Protection | 150 % full scale |

| Measuring Principle | Strain gauge bridge |

| Signal Processing | Digital 16 bit A/D converter |

| Damping | Adjustable electronic damping (Moving averaging) |

| Measuring Frequency | 5 kHz internal only |

| Display | 4 digit, 11 mm high |

| Display Update Time | Approx. 2 times per second |

| Memory | Max. 4000 values plus statistics |

| Output Signal Analog | 0 - 2 V DC (linearized) R (load) > 1 kÙ ± approx. 1 %, conversion rate approx. 100 Hz |

| Output Signal Digital | RS 232 (19200, 8, N, 1) |

| Communications Frequency | 1 to max. 80 readings/s |

| Connection Cable | Sensor to display unit 1.5 m |

| Temperature Coefficient | Gain: less than ± 0.01 % full scale /C° |

| Temperature Range | 10 - 45 °C |

| Air Humidity | 85 % RH, max. |

| Auto Power Off | Appox. after 3 minutes of non-use |

| Power Supply | 9 V E block, e. g. long-life 9 V lithium (approx. 80 hours continuous use) |

| Housing Material | Aluminum profile with plastic outer casing (PVC) |

| Weight | Approx. 370 g |

| Measuring Rollers | 2 x 22 mm ball bearing rollers, total 50 mm |

| Width of Outer Rollers | 100 mm (ball bearing rollers) |

| Reference Frame Height Adjustment | 24 mm |

| Material | Anodized aluminum |

| Reference Frame Dimensions | 110 x 140 mm |

| Weight, net (gross) | Approx. 1000 g (1900 g) |