Barcol Hardness Impressor

The new PosiTector BHI Barcol hardness tester measures the indentation hardness of soft metals (aluminum, aluminum alloys, copper, brass ), harder plastics and fiber-reinforced plastics.

Barcol hardness testing is used in a variety of applications. It is used for hardness testing of flat and slightly curved materials and in particular for the measurement of forgings and castings made of aluminum, unreinforced rigid plastics, fiber and glass fiber reinforced plastics (FRP & GRP) and hard thermoplastic (Duroplastics). Typical examples for industrial use can be found in shipbuilding, aircraft construction, tank construction and for hardness testing on plastic pipes and on the blades of wind turbines. To determine the hardness according to Barcol, the cone indenter made of hardened steel is pressed into the specimen surface using a spring system. The depth of impression is determined directly via a measuring cell.

The PosiTector BHI Barcol hardness tester offers a number of advantages over conventional analog hardness testers. It combines ease of use with the advantages of the PosiTector series, such as the functions of storing, displaying and downloading hardness values, which can be integrated into user-defined protocols using PosiSoft software solutions. Additional features that are unique to the PosiTector BHI include the ability to set a test time for testing materials that take a specific amount of time to take impressions, and automatic under-batching of the desired number of sample readings and summarizing the readings in memory (with the advanced version).

This PosiTector BHI Barcol hardness tester also comes with a durable, on-site replaceable indentation tip as well as test disks, which are made of aluminum alloy with leveling plate to check the measurement accuracy.

The PosiTector BHI is compatible with PosiTector standard measuring devices with colour display and PosiTector Advanced measuring devices and with all PosiSoft software solutions. Furthermore, this BHI Tester is solvent, acid, oil, water and dust resistant. A Shock-absorbing, protective rubber holster with belt clip and hard-shell carrying case included as well as a Long Form Certificate of Calibration. Hi-Res mode increases displayed resolution for use on applications that require a greater precision. The PosiTector body fits with all PosiTector BHI, SHD, 6000, 200, DPM, IRT, RTR, SPG, SST, and UTG probes.

Features

- Includes spare, field replaceable indenter with replacement tool

- User-adjustable measurement time with on screen countdown

- Lightweight, portable device can be used in any orientation

- Reset feature instantly restores factory settings

The PosiTector BHI is delivered with 2 test disks, glass plate, protective rubber holster with belt clip, wrist strap, 3 AAA batteries, instructions, hard shell carrying case, protective lens shield, a Long Form Certificate of Calibration, USB cable, and PosiSoft Software.

Probe - Feature Comparison Chart

| Feature Comparison Chart | Standard (1) |

Advanced (3) |

| Hi Contrast LCD Display |  Color |

Color |

| General Features | Standard (1) |

Advanced (3) |

| FAST mode - faster measurement speed for quick inspection | ||

| SCAN Mode - take continuous readings without lifting the probe | - |

|

| Hi-Lo limits audibly and visibly alerts when measurements exceed your specified limits |

|

|

| Instantly calculate average, standard deviation, min/max thickness and number of readings while measuring |

|

|

| Onscreen help, real time graphing, picture prompting and batch notes | - | |

| Memory Features & Capacity | Standard (1) |

Advanced (3) |

| Reading Storage Capacity | 1000 in one group | 250,000 in up to 1000 groups |

| Create meaningful batch names and enter notes directly on the instrument using a familiar on-screen QWERTY keyboard. | - | |

| SSPC PA2 feature set determines if film thickness over a large area conforms to user-specified min/max levels | - | |

| PSPC 90/10 feature determines if a coating system complies with an IMO performance standard for protective coatings | - | |

| Multiple stored calibration adjustments for measuring on a variety of substrate conditions | - | |

| Connection Options | Standard (1) |

Advanced (3) |

| USB port for fast, simple connection to a PC and to supply continuous power. USB cable included | ||

| WiFi technology wirelessly synchronizes with PosiSoft.net, downloads software updates, and connects to mobile devices for expanded functionality | - | |

| Bluetooth Wireless Technology for data transfer to a PC or optional portable printer | - | |

| PosiSoft Solutions | Standard (1) |

Advanced (3) |

| PosiSoft Desktop Software Desktop software for PC or Mac computer | ||

| PosiSoft USB Drive Access your PosiTector as a flash drive. View and print readings and graphs using universal PC/Mac web browsers or file explorers | ||

| PosiSoft.net (formerly PosiTector.net) Cloud-based application offering centralized management of PosiTector readings | ||

| PosiSoft Mobile Gage-based software application featured in all PosiTector Advanced instruments | - |

| Comparison chart | Standard (1) |

Advanced (3) |

| High Contrast LCD Display | Colour | Colour |

| Reading Storage Capacity | 1000 per probe | 250,000 from multiple probes in up to 1000 batches |

| Create meaningful batch names and enter notes directly on the instrument using a familiar on-screen QWERTY keyboard | - | |

| Auto Sub-Batch (automatically create sub-batches after the required number of readings are taken) | - | |

| Live graphing of measurement data | - | |

| Saves measurements in individual batches (thickness, profile, environmental, salt contamination, hardness and wall thickness) | - | |

| WiFi technology wirelessly synchronizes with PosiSoft.net, downloads software updates | - | |

| Bluetooth 4.0 Wireless Technology for data transfer to a mobile device using the PosiTector App or optional portable printer | - | |

| Integration with third-party software, drones, ROVs, PLCs, and robotic devices using several industry-standard communication protocols | - |

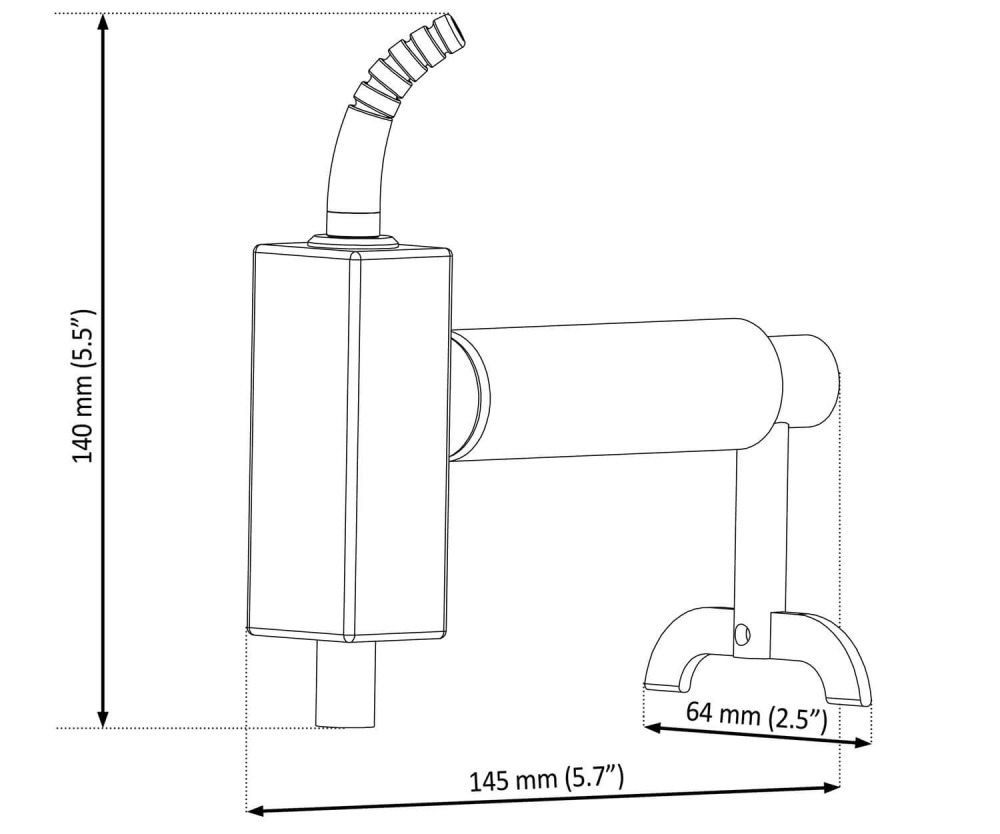

Dimensions

Specifications

| Measurement Range: | 20 - 100 Barcol |

| Resolution: | 0.1 Barcol |

| Accuracy: | ± 2 Barcol |

| Gauge dimension: | 137 x 61 x 28 mm |

| Probe dimension: | 145 x 97 x 64 mm |

| Gauge weight: | 140 g |

| Probe Headroom: | 140 mm |

| Probe Weight: | 400 g |

| Warranty: | 2 years |

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request