DTS Digital Tension Meters

This Electronic Tension Meter has been designed for applications in the textile and wire industry. Delivered with a variety of rollers and measuring ranges, it can be used in several distinct industries such as the wire, textile or carbon fiber industry.

This Electronic Tension Meter has been designed for applications in the textile and wire industry. Delivered with a variety of rollers and measuring ranges, it can be used in several distinct industries such as the wire, textile or carbon fiber industry.

Furthermore, the DTS Digital Tension Meter is hand-held and available with 12 different tension ranges from 0.2 - 200 cN up to 0.6 - 60 daN.

The built-in material thickness compensator and the calibration adjustment allow fine tuning of the calibration for materials, which differ from factory standard calibration material.

Its backlight and rotatable LCD display make it easy to read under every condition.

New functions such as programmable MIN- and MAX alarms, calibration memory for up to 4 customer made calibrations and new material catching system also assist you in the improvement of your quality control processes.

To sum it up, this DTS Tension meter delivers the critical process information required to meet today's strict quality reporting systems mandated under ISO 9000 guidelines.

Features

- Large backlight LCD Display automatically rotates in 90° steps

- Integrated material thickness compensator and calibration fine tuning allow highest precision

- Selectable MIN and MAX values with optical alarm

- Selectable measuring units: cN, daN, g, kg, N, lb

- High configurable to adjust it exactly as required

- High measuring frequency of 1 kHz (1000 measuring/sec.), intern 8 kHz

- Provides MIN-, MAX-, Peak, average and standard deviation

- 4 customer specific calibration can be saved in addition to the standard calibration

- Automatic zero adjustment in every position due to a modern special sensor

- Password protection for important functions

| Model | Range / Resolution | Head width mm* | Calibration Material PA** | Textile Industry Applications | Wire Industry Applications | Material-thickness Compensator |

| DTS-200 | 0.2 – 200.0 / 0.1 cN | 66 | max. 0.12 mm Ø | max. 200 tex | max. 0.15 mm Ø | |

| DTS-500 | 0.5 - 500 / 0.1 cN | 66 | 0.12 + 0.20 mm Ø | max. 500 tex | 0.05 – 0.25 mm Ø | |

| DTS-1000 | 10 – 1000 / 1 cN | 66 | 0.20 + 0.40 mm Ø | max. 1000 tex | 0.10 – 0.40 mm Ø | |

| DTS-2000 | 20 – 2000 / 1 cN | 66 | 0.40 + 0.70 mm Ø | max. 2000 tex | 0.30 – 0.60 mm Ø | |

| DTS-2500 | 25 – 2500 / 1 cN | 116 | 0.40 + 0.70 mm Ø | max. 2500 tex | 0.30 – 0.70 mm Ø | |

| DTS-4000 | 40 – 4000 / 1 cN | 66 | 0.50 + 0.90 mm Ø | max. 4000 tex | 0.35 – 0.90 mm Ø | |

| DTS-5000 | 50 – 5000 / 1 cN | 116 | 0.60 + 1.20 mm | max. 5000 tex | 0.40 – 1.00 mm Ø | |

| DTS-10K | 0.1 – 10.00 / 0.01 daN | 116 | 0.80 + 1.40 mm Ø | max. 10000 tex | 0.70 – 1.40 mm Ø | |

| DTS-20K | 0.2 – 20.00 / 0.01 daN | 166 | 1.20 + 1.80 mm Ø | max. 20000 tex | 1.00 – 1.80 mm Ø | |

| DTS-30K | 0.3 – 30.00 / 0.01 daN | 216 | 1.40 + 2.20 mm Ø | max. 30000 tex | 1.20 – 2.00 mm Ø | |

| DTS-50K | 0.5 – 50.00 / 0.01 daN | 216 | steel rope 1.5 mm Ø (7 x 7 x 0.2) | max. 50000 tex | 1.40 – 2.20 mm Ø | |

| DTS-60K-V1 | 0.6 – 60.00 / 0.01 daN | 280 | steel rope 2.0 mm Ø (7 x 7 x 0.3) | max. 60000 tex | 1.80 – 3.00 mm Ø | |

| All models except the DTS-200, DTS-50K and DTS-60K-V1 are equipped with a built-in material thickness compensator * Depending on model, either width of filament guide or outer distance between outside guide rollers ** Suitable for 95 % of applications - PA = Polyamid-Monofilament | ||||||

| Order-Code | Line Speed vmax. … m/min | Roller Material |

|---|---|---|

| Standard | 4000 | Hardened steel (max. Ø 4mm) |

| Code K | 3500 | Hard-coated aluminium |

| Code H | 5000 | Plasma-coated aluminium |

| Code T | 1000 | Plastic (POM) black |

| Code W | 1000 | Nickel-plated steel |

| Code ST | 1000 | Hardened steel |

| Code B | 1000 | Tempered steel |

| Code CE2 | 1000 | Aluminium ceramic-coated |

| Code ASY | 1000 | Hard-coated aluminium, asymmetrical groove (not for model DTS-200) |

| Code ASYB | 1000 | Tempered steel (for tire code), asymmetrical groove (not for model DTS-200) |

| Code V1 | 1000 | Hard-coated aluminium (only for model DTS-60K-V1) |

| Code U | 2000 | Hard-coated aluminium, radius R3 (not for model DTS-200) |

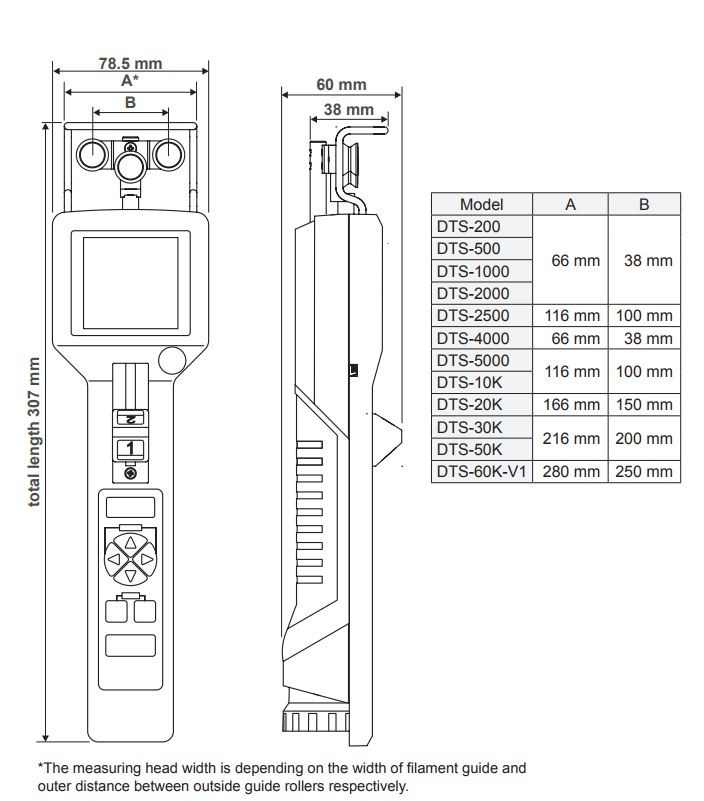

Dimensions

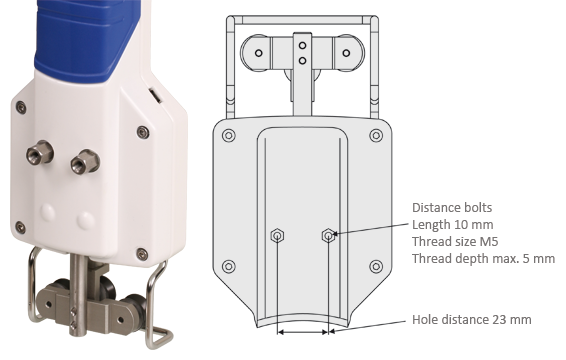

| Code MH - Online Mounting | |

|

To mount the gauge for online use, the housing can be equipped with mounting threads. There are two bolts with M5 female thread on the rear side. This feature cannot be installed afterwards. |

Specifications

| Accuracy: | For standard material from 5 % up to 100 % of FS: ± 0.5 % FS ± 1 digit remaining tension range and other calibration materials: ±3 % full scale and ±1 digit |

| Overrange: | Approx. 10 % FS*, full scale, without accuracy guarantee |

| Overload protection: | 100 % full scale |

| Memory for material curves: | 1 for standard calibration plus 4 for customized calibrations |

| Measuring units: | Force (switchable): cN, daN, g, kg, N, lb Thickness (switchable): mm, inch |

| Measuring principle: | Strain gauge bridge |

| Signal processing: | Digital, 16 bit A/D converter |

| Measuring frequency: | Max. 1 kHz (1000 measurements/sec.), intern 8 kHz |

| Measuring roller deflection: | Max. 0.2 mm |

| Display: | Graphic LCD |

| 3 different displays: | Numeric Digital with graph (time-voltage) X-Y-diagram |

| Display update rate: | Approx. 2 times per second |

| Memory: | MIN, MAX, PEAK, AVG and LAST |

| Damping: | Adjustable electronic damping (averaging) |

| Cal. Adjustment: | ± 10 steps in 1 % increment |

| Thickness compensation: | Max. 2.5 mm (not available for DTS-200, DTS-50K and DTS-60K-V1) |

| Auto power off: | Approx. 3 minutes of non-use |

| Temperature coefficient: | Gain: less than ± 0.01 % FS* /°C |

| Zero point: | less than ± 0.03 % FS* /°C |

| Temperature range: | 10 – 45 °C |

| Air humidity: | 85 % RH, max. |

| Power supply: | LiPo accumulator (approx. 40 h continuous use), charging time approx. 3 1/2 h AC adapter 100 – 240 V AC, adapter (EU, USA, UK) |

| Housing material: | Die-cast aluminum |

| Housing dimensions: | As per above shown dimensions sheet |

| Weight, net (gross): | Until DTS-50K approx. 875 g / 1550 g DTS-60K-V1 approx. 1040 g / 2700 g |

Buy Now

Availability: Available: 1 - 3 days, Delivery time: 1 - 3 weeks, special order request